As a reliable environmental air cooling supplier, fan supplier UnitedStar has been continuously designing, developing and producing new and cost-effective air cooling products, including stand fans, ceiling fans, charging fans, table fans, mobile air conditioners and dehumidifiers, to meet the needs of global customers to improve the environment. This article will introduce the influence of the shape and material of the fan blade on the performance of the fan.

1. Principle of fan

The principle of the fan is that the energizing coil is forced to rotate in the magnetic field. After the electric fan is energized, the positive and negative alternating current generates a magnetic field, which causes the energizing coil of the motor to rotate under force, and the rotating shaft rotates together with the fan blades, and the electrical energy is converted into mechanical energy. In the process of energy conversion, part of the energy is converted into thermal energy and released to the outside.

Why is it cool when people use fans? The normal body temperature of a person is 37 degrees, but the temperature when the body surface is exposed may be a little lower, such as about 36 degrees. When the ambient temperature is lower than 36 ° C and the air humidity is not saturated, the fan is conducive to the evaporation of sweat by increasing the air convection. Evaporation of sweat will take away a lot of heat and make people feel cool.

2. Types of fan blades

1. According to the purpose, there are separation type, mixed flow type and axial flow type blades.

2. According to the wind direction, it is divided into axial flow fan and cross flow fan.

3. According to the shape, it is divided into thin right angle, thick corner and thin corner.

4. According to the material, it is divided into metal blade, plastic blade, wood chip, etc.

Thin right angle fan blade is the earliest product, but it is still not out of date. The fans using this kind of fan blade can only behave in a regular manner in terms of noise, wind pressure, air volume and service life, and are suitable for those products with low heating capacity.

The thick curved fan blade has the best heat dissipation capacity, because it produces a large wind pressure and sufficient air volume, which is also beneficial to the improvement of the cold and heat exchange speed. However, the thick curved blade will bring more noise, and the centrifugal force on the shaft center during rotation is large, and the wear is serious, which also has a certain impact on the service life. This kind of blade is often used on fans that provide a larger air volume.

3. Influence of fan blade design on fan

1) Wind speed

The speed of the wind speed depends on the speed of the fan blades, which in turn relates to the area, shape and even height of the fan blades.

2)Air volume

The air volume is mainly affected by the area and wind speed. At the same speed, the larger the blade curvature, the larger the air volume and pressure of the fan. There are two factors affecting the wind force, one is the fan blade size, the other is the wind speed. The larger the size of the fan blade, the larger the sweeping area. Under the same wind speed, the greater the wind force. If the fan blades are the same size, the faster the wind speed, the stronger the wind.

Therefore, if the motor power, wind speed and fan blade angle are consistent, the wind force will be larger for the wider fan blade, and smaller for the slender fan blade. Slender blades are usually found in larger fans to reduce weight. For household use, wide blades are usually used to improve efficiency and reduce noise. The smaller the fan, the more blades can be made.

3) Wind pressure

The wind pressure reflects the strong index of the fan. Generally, when the blade spacing is not too large, the multi blade design scheme will be adopted to avoid affecting the air volume and wind pressure. At the same time, the number of blades is often the base number, which is to maintain the balance of the entire fan system.

4) Wind and current

Air flow is the air flow driven by the rotation of the fan, which determines the wind blowing distance and area of the fan. It is mainly affected by the arc of the fan blade. Generally speaking, the arc of the rotation and bending can effectively concentrate the air flow and make the fan have good heat dissipation performance.

4.Influence of fan blade parameters on the performance of electric fans

1. Blade curvature: within a certain range, the larger the blade curvature, the greater the kinetic energy of the gas at the same speed, that is, the less the air volume and the greater the wind pressure; At the same time, the greater the resistance of the blade, the greater the torque of the motor.

2. Blade inclination: the greater the inclination angle, the greater the pressure difference between the upper and lower surfaces of the blade, and the greater the wind pressure at the same speed; However, if the pressure on the surface is too high, backflow may occur, which will reduce the performance of the fan. Therefore, the blade inclination should also be raised within a certain limit. Installation angle (inclination angle of blade). Generally speaking, it is a question of how to maximize the conversion of air into axial flow when the fan blade rotates. It can be seen that the inclination degree between the blade root and the maximum outer diameter of the fan blade in the figure is different, that is, the inclination angle of each radius is different.

3. Blade spacing: if the distance between blades is too small, it will cause airflow disturbance, increase the friction on the blade surface and reduce the fan efficiency; If the distance between blades is too large, the pressure loss will increase and the wind pressure will be insufficient.

4. Number of blades: the increase of fan blades generally has a great impact on the air volume. At the same speed, the more the fan blades, the more the air volume. This is because the fan blades divide the air flow into several parts, the pressure of the air flow on the fan blades will be reduced correspondingly, and the friction between the air flow and the fan blades will be reduced correspondingly. The air duct will naturally be smoother and the air volume will be more.

The section curves and inclination angles of various fan blades are basically the same, and the width of each blade often depends on the height of the fan blade. In order to ensure that the blade spacing will not be too large and affect the wind pressure, fans with small diameter to height ratio (relatively thin) usually adopt the method of increasing the number of blades to compensate. Regardless of the number of blades, the number of blades of the axial flow fan is often odd, such as 3, 7 and 11. This is because if the even number of symmetrical blades are used and the balance is not properly adjusted, it is easy to cause resonance of the system. If the blade material is unable to resist the fatigue caused by vibration, the blade or spindle will be broken. Therefore, the design of the odd number of blades with asymmetric axis is usually adopted. This principle is widely used in all kinds of fan blade design, including the propeller of some straight engines.

This 7-blade stand fan of UnitedStar has stronger wind force, 90 degrees oscillation, and is equipped with 120-minute timing and remote control.

5. Blade end clearance: how to adjust the clearance between the fan blade and the outer frame is a major problem in fan design. If the clearance is too small, the air flow will rub against the blades and the outer frame, increasing the noise; Increasing the gap will reduce the fan efficiency due to the influence of the flyback air flow.

6.Blade radian: in addition to a certain curvature on the cross section, the fan blade does not extend straight along the radial direction in the top view plane, but slightly curved toward the rotating direction, with a certain radian. If the blade extends straight along the radial direction, the air flow driven by the fan rotation will be scattered on the side of the air outlet, with a short air supply distance and no concentrated “force”; If the current product version is slightly curved, it can ensure that the blown air flow is concentrated in the columnar space in front of the air outlet, and increase the air supply distance and air pressure.

7.Motor diameter: the diameter of the main shaft mainly depends on the power of the fan motor – a high-power motor needs a larger stator winding coil, which will inevitably occupy more space. In the case that it is impossible to expand vertically (increase the height), it has to expand horizontally (increase the area)

8. Blade smoothness: This is an index affected by non design factors, which basically depends on the mold forming and post-treatment process of the manufacturer. Outside the design curve, the unevenness on the blade will generate turbulence during rotation, increase friction, reduce fan efficiency and damage fan performance.

9. Deflection angle: that is, the bottom edge of the blade is scattered in a certain arc, non-linear radiation. Here, it can be understood as the shape of the bottom edge, which can be straight or deflected into various angles; Can be arc-shaped, different radians; It can be elliptical, U-shaped, W-shaped and various.

The fan blades with long and fan-shaped blades have large air volume. The width and width of the electric fan mainly depend on the environment. The narrow blade is selected for the home with low noise and small air volume. The blade can be widened appropriately for work or entertainment. The air volume is large but the noise will also increase.

This hot selling 18 inch 3-in-1 metal stand fan of UnitedStar (which can be used as stand fan, floor fan and wall fan) has strong air volume, stable and heavier base, 90 degree oscillation, and accessories are produced by UnitedStar. It is the first choice for cooling in hot summer.

In general, the narrow fan has low noise and small air volume. Wide fan blades are noisy and have large air volume, which can be selected according to your actual situation.

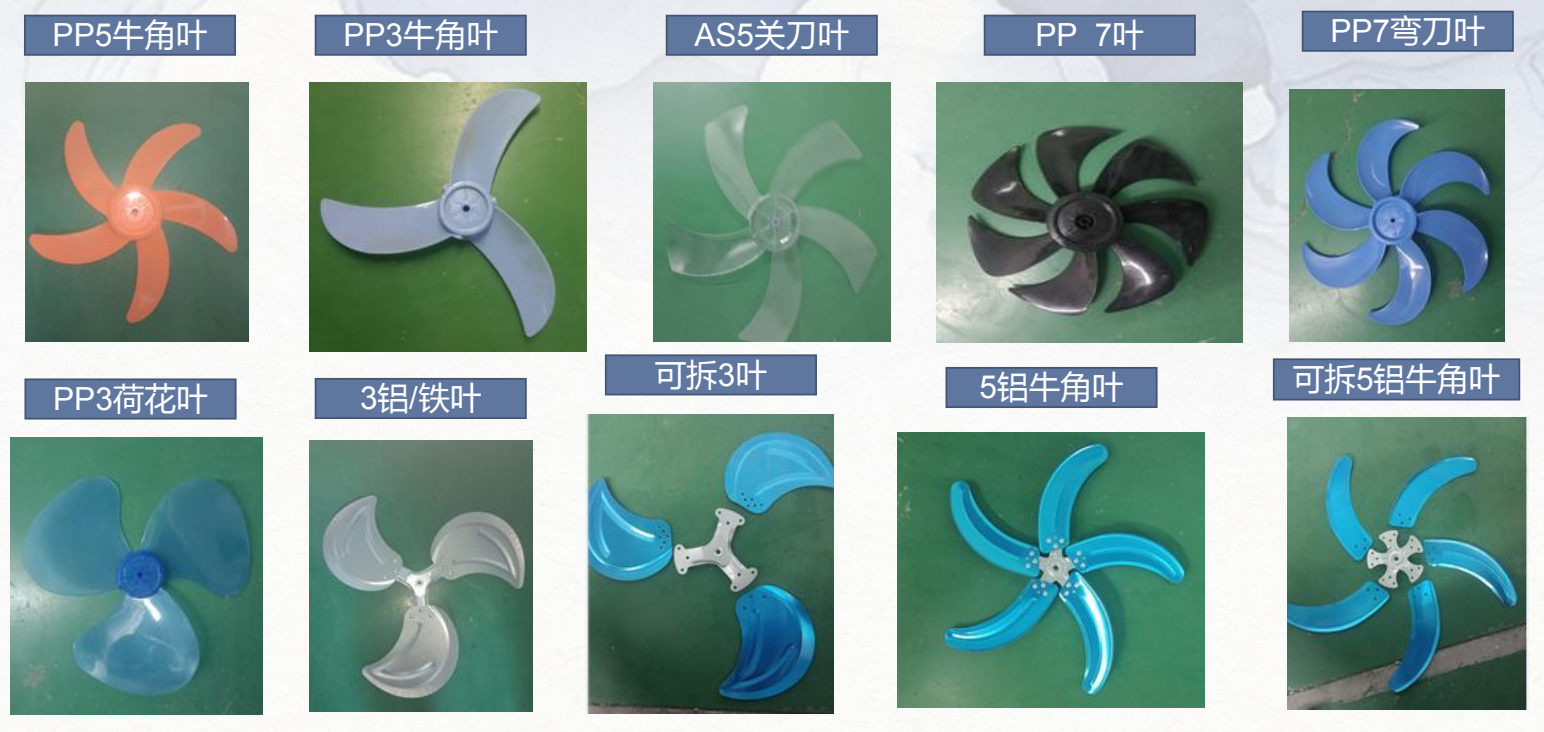

5、 Fan blades of various shapes and materials of UnitedStar

1) Horn shaped fan blade: it has larger air supply range, larger air volume and softer air supply than other fans, because the horn shape has small area, large angle and small resistance.

2. PP fan blade is produced by injection molding with (polypropylene) new material, with good quality, low noise, high safety, not easy to deform, light weight and power saving.

1) Low noise.

The metal blades are generally thin, because the whole load will increase when they are heavy, while the plastic blades are generally thicker than the blades, and they are easy to break when they are light. The sound of cutting air by metal sheet is much louder than that of thick plastic blade, and the sound is even louder when there is slight shaking.

2) High safety

Metal blades are easy to scratch hands during maintenance. When it is not installed properly or suddenly falls off during use, or something is accidentally involved during rotation, the blade is easy to break and fly out, so it is dangerous for the metal blade to fly out.

3) Not easy to deform

The plastic blades are all cast by fixed molds without deformation. Unless baked by fire, the metal blades are easy to deform due to their good flexibility, wind resistance, weather change and other factors.

3. ABS fan blade: hard, easy to color, with 90% high gloss, non-toxic, tasteless, low water absorption

4. Aluminum alloy fan blade: the material is harder than plastic, and the air outlet is stable and strong. More durable than plastic, aging resistant, long-term use without deformation.

If it is not a high-power fan, the advantages of plastic are higher than the cost performance ratio; If the power is large, the performance advantages of aluminum alloy will be clearly reflected.

For example, this self-designed fan blade of UnitedStar has large air volume, low noise, energy saving and power saving, and is not easy to deform. At present, it has been recognized by many overseas customers.

Fan manufacturer UnitedStar have launched a new multi-blade, which can be placed in any fans, if you like we can customized the fan you need.

UnitedStar Introduction

As an industry leader, fan manufacturer UnitedStar has a strong production capacity of more than 16000 fans per day. Our factory covers an area of 47200m² with BSCI and ISO9001, and have advanced automated production lines in which robots assemble components. The Annual output exceeds 10 million units. With over 14 years’ R & D experience, all kinds of fans are available from fan company UnitedStar, including standing fans, ceiling fans, DC fans and table fans, etc. Every year our products enjoy a good reputation all over China and are exported to every corner of the world. We believe that it is because we insist on quality first, making sure that all of our products meet international standards. China electric fan factory UnitedStar also provides customized service for customers who want their own brand or logo on their fans. If you need any help with choosing a suitable product or have any questions about us, please feel free to contact us at any time and we will try our best to assist you. Please be assured that your inquiry will be replied to within 24 hours.