Table of Contents

Introduction

Portable air conditioner, also known as mobile air conditioner, is a versatile cooling device designed for easy mobility and installation. It consists of several components, each serving a specific function to ensure efficient cooling. This article provides an in-depth understanding of portable air conditioner, including its working principle, refrigerants, energy efficiency, filter, motor, compressor, Heat exchanger.

Definition and Working Principle of Portable Air Conditioner

Definition

Portable air conditioners have become increasingly popular due to their convenience in cooling individual rooms or smaller spaces. They offer a flexible and cost-effective alternative to central air conditioning systems.

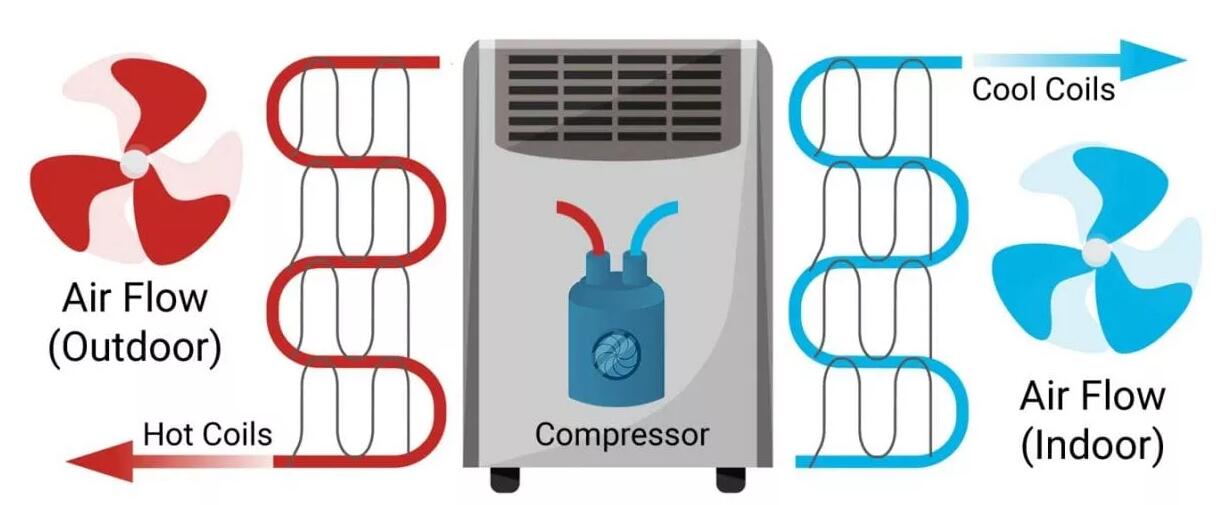

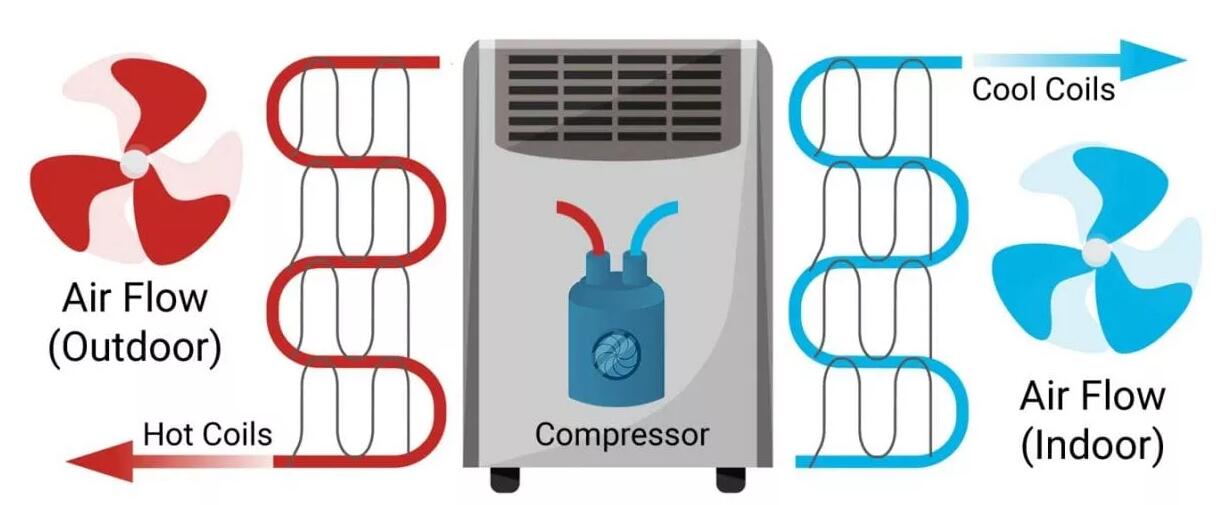

Mobile air conditioners are compact cooling devices that can be easily moved from one location to another. These units typically consist of four main components: a compressor, an evaporator, a condenser, and a refrigerant circuit.

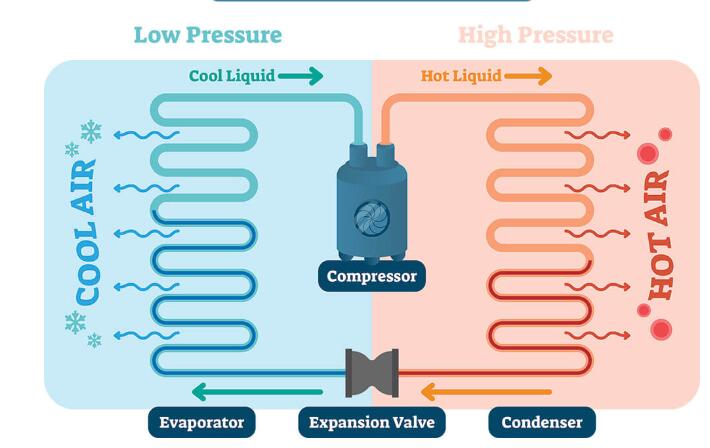

Working Principle of Air Conditioner

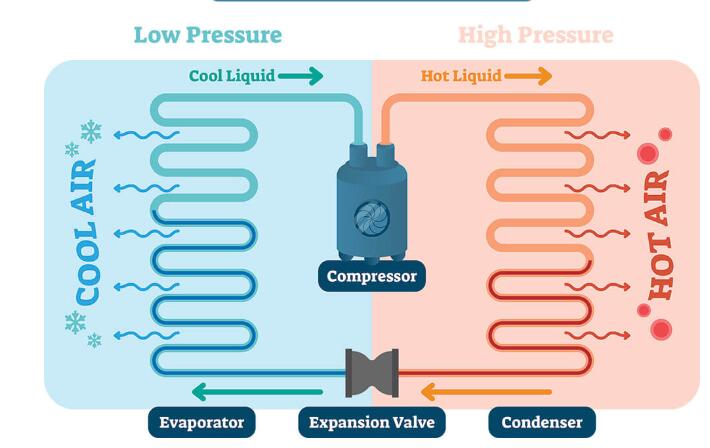

The compressor compresses the gaseous refrigerant into a high-temperature and high-pressure gaseous state, and sends it to the condenser for cooling. After cooling, it becomes a medium-temperature and high-pressure liquid refrigerant and enters the drying bottle for filtration and dehumidification. The medium-temperature liquid refrigerant passes through the expansion valve. (Throttling parts) Throttle-down low-temperature and low-pressure gas-liquid mixture (more liquid), through the evaporator absorbs the heat in the air and vaporizes, becomes a gaseous state, and then returns to the compressor to continue compression and continue to cycle for refrigeration. When heating, there is a four-way valve so that the flow direction of Freon in the condenser and evaporator is opposite to that during cooling, so when heating, the outdoor blows cold air, and the indoor unit blows hot air.

Working Principle of Portable Air Conditioner

The working principle of a portable air conditioner is based on the basic principles of refrigeration. It involves the transfer of heat from the indoor air to the outdoor environment, resulting in the cooling of the indoor space.

Here is a step-by-step explanation of the working principle:

Air Circulation: The portable air conditioner draws in warm indoor air through a vent or intake grille using a fan.

Cooling Process: The warm air passes over an evaporator coil containing a refrigerant, typically a liquid coolant such as R-410A. The refrigerant absorbs the heat from the air, causing it to evaporate and turn into a low-pressure gas.

Compressor: The low-pressure gas is then compressed by a compressor, which increases its temperature and pressure. This process requires energy to run the compressor.

Heat Dissipation: The hot, pressurized gas then flows into a condenser coil located outside the room. As the gas cools down, it releases heat to the outdoor environment.

Expanding the Gas: The refrigerant, after losing heat and pressure, becomes a cool, low-pressure liquid again.

Recirculation: The cool liquid refrigerant is passed through an expansion valve, which controls its flow rate and reduces its pressure. This process prepares the refrigerant to absorb heat from the indoor air again.

Dehumidification: As the warm air passes over the cold evaporator coil, the moisture in the air condenses on the coil’s surface, reducing the humidity in the room.

Exhaust: The cooled and dehumidified air is then released back into the room through an exhaust vent.

This cycle repeats continuously until the desired indoor temperature is achieved. Portable air conditioners are designed for easy installation and mobility, allowing users to move them from one room to another, making them a flexible cooling solution for various spaces.

Comparison of mobile air conditioner refrigerants

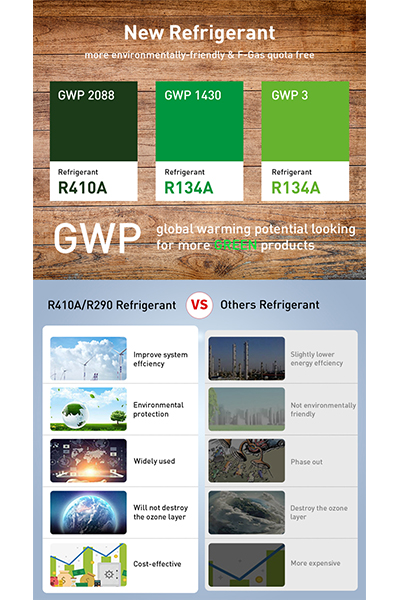

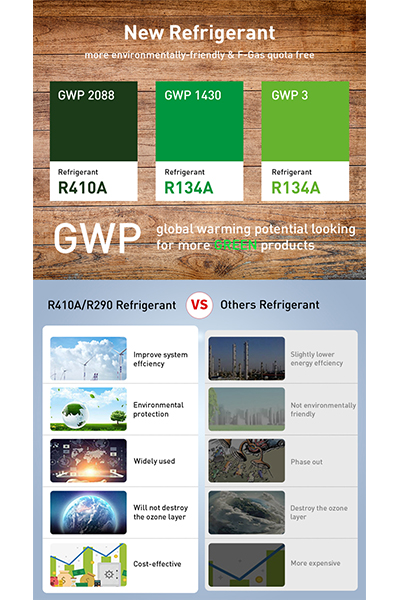

There are several types of refrigerants used in mobile air conditioning systems. Here is a comparison of some commonly used refrigerants:

R-134a: This is a hydrofluorocarbon (HFC) refrigerant widely used in automotive air conditioning systems. It has low ozone depletion potential (ODP) and is considered environmentally friendly. However, it has a relatively high global warming potential (GWP).

R-1234yf: This is another HFC refrigerant that is gaining popularity as a replacement for R-134a. It has a significantly lower GWP, making it more environmentally friendly. It is used in many newer vehicle models.

R-410A: This is a hydrofluorocarbon blend used in residential and commercial air conditioning systems. It has no chlorine content, which makes it ozone-friendly. It has a relatively high GWP compared to some other refrigerants.

R-22: This hydrochlorofluorocarbon (HCFC) refrigerant has been widely used in older air conditioning systems. However, it is being phased out due to its ozone-depleting properties and high GWP. It is being replaced by more environmentally friendly alternatives.

R-290: This is a hydrocarbon (HC) refrigerant, specifically propane, which has a very low GWP and zero ODP. It is considered one of the most environmentally friendly refrigerants. However, due to its flammability, it requires special safety precautions during handling and storage.

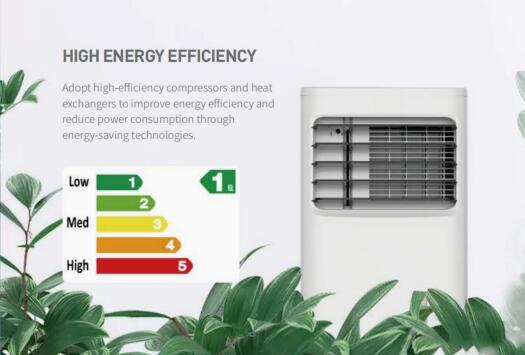

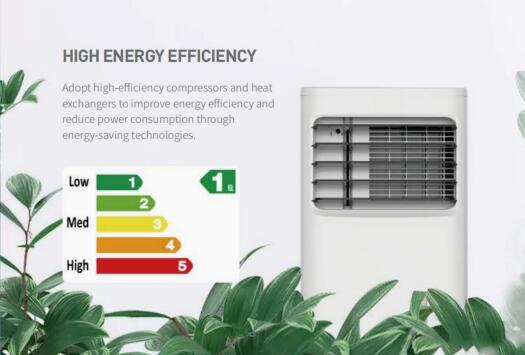

Portable Air conditioner energy efficiency rating introduction

An air conditioner energy efficiency rating, also known as an EER, is a measurement of how efficiently an air conditioning system uses energy to cool a space. It is a crucial factor to consider when purchasing an air conditioner, as a higher EER indicates a more energy-efficient unit.

The EER is calculated by dividing the cooling capacity of the air conditioner (in British Thermal Units, or BTUs) by the power input (in watts) required to run the unit. The result is a ratio that represents the cooling output per unit of energy consumed.

A higher EER means that the air conditioner can provide more cooling power while using less electricity. This translates into lower energy bills and a reduced environmental impact. In addition, energy-efficient air conditioners tend to have longer lifespans and require less maintenance.

The United States Department of Energy (DOE) has set minimum EER requirements for air conditioners, with higher minimums for larger units. These standards help consumers make informed decisions and promote the use of energy-efficient appliances.

When shopping for an air conditioner, it is important to look for the EER label or rating. The higher the EER, the more efficient the unit is. However, it is worth noting that higher EER ratings often come with a higher price tag. Therefore, it is essential to consider the balance between energy efficiency, initial cost, and long-term savings.

In conclusion, an air conditioner’s energy efficiency rating is a vital consideration for anyone looking to purchase a cooling system. It not only affects energy consumption and cost but also contributes to environmental sustainability. By choosing an air conditioner with a high EER, consumers can enjoy efficient cooling while minimizing their carbon footprint.

Portable Air conditioner filter introduction

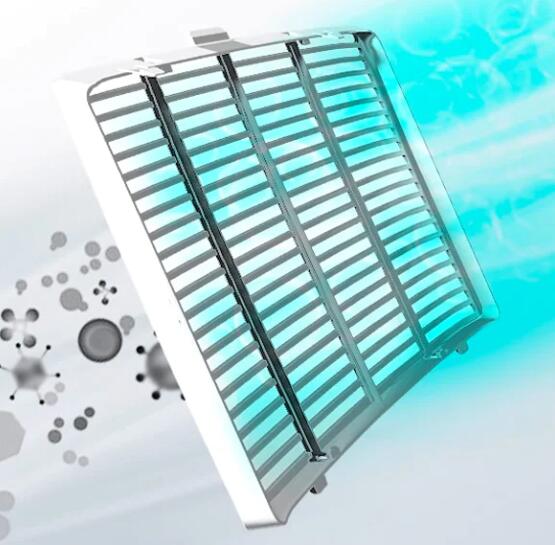

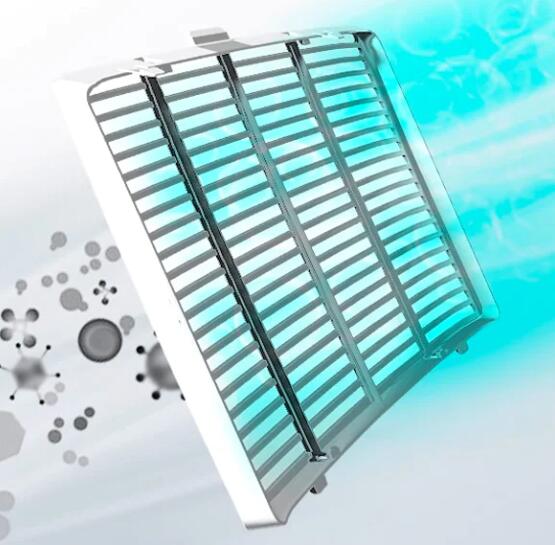

An air conditioner filter is an essential component of an air conditioning system that helps improve indoor air quality by trapping dust, pollen, pet dander, and other airborne particles. It plays a crucial role in maintaining clean and healthy air in a space, as well as ensuring the proper functioning and efficiency of the air conditioner.

The primary function of an air conditioner filter is to capture and remove contaminants from the air as it circulates through the system. This helps to prevent these particles from being recirculated back into the room, reducing the risk of allergies, respiratory issues, and overall discomfort.

Air conditioner filters come in various types, including Negative Ion Filter, Activated Carbon Filter, Silver Ion Filter, Elimination Filter, and high-efficiency particulate air (HEPA) filters. Each type has different levels of filtration efficiency and lifespan, which should be considered based on individual needs and preferences.

Negative Ion Filter: This type of filter is designed to release negative ions into the air. Negative ions are believed to have various health benefits, such as improving mood, reducing stress, and enhancing overall well-being. They also help to remove airborne particles by causing them to stick together and fall to the ground, making them easier to clean.

Activated Carbon Filter: An activated carbon filter is effective in removing odors, chemicals, and volatile organic compounds (VOCs) from the air. It consists of a porous carbon material that adsorbs these pollutants, trapping them and preventing them from recirculating into the room. This type of filter is particularly useful in spaces with strong odors or for individuals with sensitivities to chemicals.

Silver Ion Filter: Silver ion filters are designed to inhibit the growth of bacteria, viruses, and mold within the air conditioning system. The filter contains silver-coated fibers or particles that release silver ions into the air, which have antimicrobial properties. This helps to maintain cleaner air and reduce the risk of respiratory infections.

Elimination Filter: High-density anti-mildew and washable filter screen is used; it can effectively remove dust. When the filter screen accumulates a certain amount, it is convenient to rinse the filter screen with clean water; to achieve cleaning, just put it back after drying.

HEPA Filter: High-Efficiency Particulate Air (HEPA) filters are known for their exceptional filtration capabilities. These filters can capture very small particles, including dust, pollen, pet dander, and even some bacteria and viruses. HEPA filters are highly effective in improving indoor air quality and are commonly used in environments where air purity is crucial, such as hospitals and laboratories.

It’s important to note that not all air conditioners come with these specialized filters as standard. Some filters can be added or replaced separately, depending on the specific needs and preferences of the user. When considering these specialized filters, it’s advisable to consult the air conditioner manufacturer or a professional to ensure compatibility and proper installation.

Regular maintenance and cleaning of the air conditioner filter are essential to ensure its optimal performance. Over time, the filter can become clogged with dirt and debris, reducing airflow and forcing the air conditioner to work harder, resulting in decreased energy efficiency. Therefore, it is recommended to clean or replace the filter periodically, following the manufacturer’s guidelines.

In addition to improving indoor air quality and energy efficiency, a clean and well-maintained air conditioner filter can also extend the lifespan of the air conditioner itself. By preventing the accumulation of dust and debris on the internal components, the filter helps to keep the system running smoothly and reduces the risk of breakdowns or malfunctions.

In conclusion, an air conditioner filter is a vital component of an air conditioning system that helps improve indoor air quality and maintain the efficiency of the unit. Regular cleaning and maintenance of the filter are crucial to ensure its effectiveness and prolong the lifespan of the air conditioner.

Motor of portable aircon introduction

Motor of portable aircon is mainly composed of the stator and the rotor. The stator is mainly composed of the iron core and the coil. The rotor is mainly composed of the shaft, the bearings, the commutator, the brushes, and other parts. The working principle of the portable air conditioner motor is that the current is passed through the coil of the stator to generate magnetic field, and the rotor is rotated by the magnetic force to generate airflow. The portable air conditioner motor is an important part of the portable air conditioner, and its performance directly affects the performance of the portable air conditioner.

Portable air conditioners typically use an electric motor for their operation. The motors used in portable ACs are typically classified based on their type and design. Here are three common motor classifications in portable air conditioners:

Single-phase induction motor: This type of motor is widely used in portable ACs due to its simplicity and cost-effectiveness. It operates on a single-phase AC power supply and consists of a stator (stationary part) and a rotor (rotating part). Single-phase induction motors provide reliable cooling and are commonly found in smaller portable AC units.

Permanent magnet motor: Some portable AC models utilize permanent magnet motors. These motors incorporate permanent magnets in the rotor, which enhance their energy efficiency and reduce power consumption. Permanent magnet motors are known for their compact size, lightweight, and ability to provide efficient cooling in portable air conditioners.

Brushless DC motor (BLDC): Brushless DC motors are becoming increasingly popular in portable air conditioners. These motors feature electronic commutation and do not require brushes for operation. BLDC motors offer higher energy efficiency, reduced noise levels, and longer lifespan compared to traditional brushed motors. They are known for their precise speed control, making them suitable for variable-speed compressor applications in portable ACs.

It’s important to note that while these motor classifications are commonly used in portable air conditioners, manufacturers may use different motor types or variations based on their specific design requirements.

UnitedStar’s portable aircon uses all copper wire motor, running evenly and stably. Combined into a powerful refrigeration stably. Combined into a powerful refrigeration system, the air supply is more stable and safer, and the efficiency is higher.

The compressor of portable ac's introduction and classification

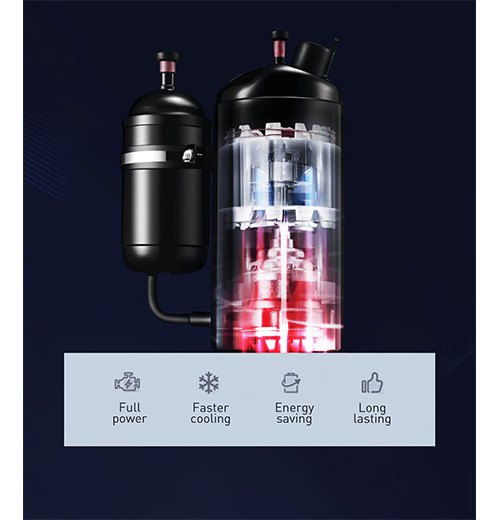

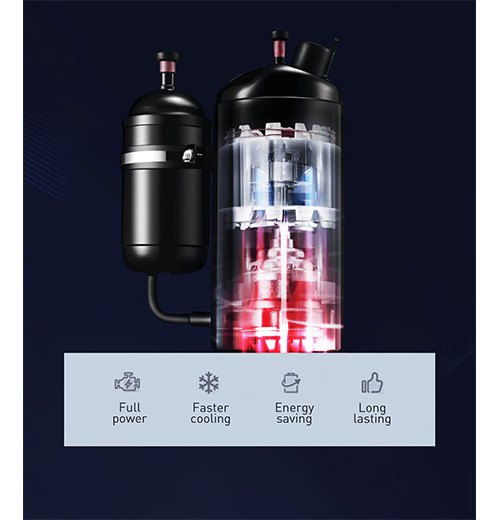

Portable AC compressors can be classified based on their design and technology. Here are some common types:

Rotary Compressor: This type of compressor uses a rotating vane to compress the refrigerant. It operates with high efficiency and is known for its quiet operation. Rotary compressors are often found in higher-end portable AC units.

Reciprocating Compressor: Reciprocating compressors use a piston-cylinder arrangement to compress the refrigerant. This type of compressor is widely used in various cooling systems, including portable air conditioners. It offers good cooling performance but tends to be noisier compared to rotary compressors.

Scroll Compressor: Scroll compressors use two spiral-shaped scrolls to compress the refrigerant. They are known for their reliability, durability, and quiet operation. Portable air conditioners equipped with scroll compressors are often more expensive but provide efficient cooling.

Inverter Compressor: Inverter compressors are designed to vary their speed based on the cooling demand. By adjusting the compressor’s speed, they achieve precise temperature control and help save energy. Portable AC units with inverter compressors are becoming increasingly popular due to their energy efficiency and quieter operation.

It’s important to note that the availability of specific compressor types might vary among different portable AC models and manufacturers. When choosing a portable AC, considering the compressor type and its associated features can help you select a unit that fits your cooling needs and preferences.

UnitedStar’s portable ac adopts a high-efficiency rotary compressor, uses permanent magnet materials, is durable and does not demagnetize, and has more efficient power during operation, powerful cooling and heating, and quiet noise reduction.

Heat exchanger of portable aircon introduction

A heat exchanger is a device used to transfer heat between two or more fluids that are at different temperatures, without them mixing with each other. It facilitates the efficient transfer of thermal energy from one fluid to another, either to heat or cool the fluids, depending on the application.

Heat exchangers are commonly used in various industries and applications, including heating, ventilation, and air conditioning (HVAC) systems, refrigeration units, power plants, chemical processing plants, and automotive engines, among others.

The basic principle of a heat exchanger involves the exchange of heat through a solid wall that separates the two fluids. The wall is usually made of a thermally conductive material, such as metal, and can be designed in various configurations to maximize heat transfer efficiency.

Heat exchangers can be classified into different types based on their design and flow arrangements. Some common types include:

Shell and Tube Heat Exchanger: This type consists of a shell (a cylindrical outer vessel) and multiple tubes inside it. One fluid flows through the tubes, while the other fluid flows around the tubes in the shell. This design offers high heat transfer efficiency and is widely used in various industries.

Plate Heat Exchanger: It consists of multiple thin plates, usually made of metal, stacked together with small gaps between them. The fluids flow through alternate channels formed between the plates, ensuring efficient heat transfer due to a large surface area.

Finned Tube Heat Exchanger: This type includes tubes with extended surfaces (fins) attached to the outer surface. The fins increase the heat transfer surface area, allowing for more effective heat exchange.

Air-to-Air Heat Exchanger: Also known as a heat recovery ventilator (HRV) or an energy recovery ventilator (ERV), this type transfers heat between two separate airstreams, typically in HVAC systems. It helps to recover the heat from exhaust air and pre-condition the fresh incoming air.

Heat exchangers play a crucial role in the efficient utilization of energy and conservation of resources. They enable the transfer of heat between fluids while minimizing energy losses, contributing to increased process efficiency and reduced energy consumption.

UnitedStar’s Double-row heat exchanger, toothed inner spiral copper tube, can effectively improve heat exchange efficiency and defrosting speed. Have great refrigeration.

Portable air conditioner manufacturer UnitedStar’s mobile air conditioners stand out among the competition due to their exceptional features and functionality. Here are some key advantages and reasons why customers should consider choosing UnitedStar:

BSCI Certification: UnitedStar holds the Business Social Compliance Initiative (BSCI) certification, ensuring ethical and sustainable manufacturing practices.

R290 Innovative Refrigerant: UnitedStar mobile air conditioners utilize R290, an eco-friendly refrigerant with low environmental impact and excellent cooling performance.

Class A Energy Efficiency: UnitedStar units are rated Class A for energy efficiency, promoting energy savings while providing powerful cooling performance.

5 Functions in 1: UnitedStar mobile air conditioners offer five functions – refrigeration, heating, air supply, dehumidification, and purification. This versatility ensures year-round comfort and excellent air quality.

Activated Carbon and UVC Sterilizing Function: The inclusion of activated carbon and UVC sterilization technology in UnitedStar units guarantees cleaner and healthier air by eliminating harmful particles and bacteria.

Easy Mobility and Assembly: UnitedStar mobile air conditioners are designed for user convenience. With lightweight construction and smooth-rolling casters, they can be effortlessly moved from one room to another. Additionally, the units feature easy assembly for quick installation.

WIFI Function and LED Display: UnitedStar portable ac comes equipped with WIFI connectivity and LED displays, enabling remote control and providing a user-friendly interface for convenient operation.

Why choose UnitedStar

United Star Industrial group LTD. is an enterprise focusing on research and development, design, production, and sales of environmental household appliance products. The group consists of Zhongshan United Star Electrical Appliance Manufacturing CO., LTD (China high-tech enterprise), Zhongshan United Star CO., LTD., Guangzhou Link-top INT’l forwarder co., LTD. (a non-vessel carrier) and Guangzhou Unitedstar co., LTD.(foreign trade sales).

Portable air conditioner factory UnitedStar has always adhered to the values of ” Deliver Best To Customer ,Be Efficient, Be Enterprising ,Be Reliable, Be Dedicated”. United Star has more than 11 years experience in home appliance product development. At present, United Star has a perfect internal structure and has passed the ISO9001 quality system of nearly 41237 square meters of plant, which includes six workshops of hardware, motor, injection molding, net cover, and final assembly. United Star has the most advanced domestic R290 mobile air conditioning production line, as well as an enthalpy difference laboratory.

We have 1133 kinds of products, among them, 82 have their property rights. We mainly produce portable air conditioner, air cooling fans, electric fans, ceiling fans, rechargeable fans, solar fans, and BLDC motors. The group has its own freight forwarding company and has more initiative in trailer and sea transportation. United Star has six registered trademarks, more than 30 product patents, GS/CE/CB/SAA/RoHS/SASO/CCC, and other certificates.

Portable air conditioner manufacturer United Star has six R&D engineers, an average of 13 new products are developed every year. Our products are exported to 126 countries, we wholeheartedly for customers to provide OEM and ODM services, have cooperated with famous enterprises at home and abroad, such as French Carrefour supermarket, German Lidl supermarket, Indian Orient company, and so on. Since 2019, the sales growth rate of our own

brand United Star in the global market has exceeded 250% for three consecutive years. Meanwhile, we have cooperative assembly bases in Indonesia, Tunisia, Mexico, Nigeria, and other regions. ” To be the most reliable environmental air cooling appliance provider. Committed to the comfort and environmental protection of the family and the earth environment ” is our persistent goal.

Working Principle of Portable Air Conditioner

The working principle of a portable air conditioner is based on the basic principles of refrigeration. It involves the transfer of heat from the indoor air to the outdoor environment, resulting in the cooling of the indoor space.

Here is a step-by-step explanation of the working principle:

Air Circulation: The portable air conditioner draws in warm indoor air through a vent or intake grille using a fan.

Cooling Process: The warm air passes over an evaporator coil containing a refrigerant, typically a liquid coolant such as R-410A. The refrigerant absorbs the heat from the air, causing it to evaporate and turn into a low-pressure gas.

Compressor: The low-pressure gas is then compressed by a compressor, which increases its temperature and pressure. This process requires energy to run the compressor.

Heat Dissipation: The hot, pressurized gas then flows into a condenser coil located outside the room. As the gas cools down, it releases heat to the outdoor environment.

Expanding the Gas: The refrigerant, after losing heat and pressure, becomes a cool, low-pressure liquid again.

Recirculation: The cool liquid refrigerant is passed through an expansion valve, which controls its flow rate and reduces its pressure. This process prepares the refrigerant to absorb heat from the indoor air again.

Dehumidification: As the warm air passes over the cold evaporator coil, the moisture in the air condenses on the coil’s surface, reducing the humidity in the room.

Exhaust: The cooled and dehumidified air is then released back into the room through an exhaust vent.

This cycle repeats continuously until the desired indoor temperature is achieved. Portable air conditioners are designed for easy installation and mobility, allowing users to move them from one room to another, making them a flexible cooling solution for various spaces.

Working Principle of Portable Air Conditioner

The working principle of a portable air conditioner is based on the basic principles of refrigeration. It involves the transfer of heat from the indoor air to the outdoor environment, resulting in the cooling of the indoor space.

Here is a step-by-step explanation of the working principle:

Air Circulation: The portable air conditioner draws in warm indoor air through a vent or intake grille using a fan.

Cooling Process: The warm air passes over an evaporator coil containing a refrigerant, typically a liquid coolant such as R-410A. The refrigerant absorbs the heat from the air, causing it to evaporate and turn into a low-pressure gas.

Compressor: The low-pressure gas is then compressed by a compressor, which increases its temperature and pressure. This process requires energy to run the compressor.

Heat Dissipation: The hot, pressurized gas then flows into a condenser coil located outside the room. As the gas cools down, it releases heat to the outdoor environment.

Expanding the Gas: The refrigerant, after losing heat and pressure, becomes a cool, low-pressure liquid again.

Recirculation: The cool liquid refrigerant is passed through an expansion valve, which controls its flow rate and reduces its pressure. This process prepares the refrigerant to absorb heat from the indoor air again.

Dehumidification: As the warm air passes over the cold evaporator coil, the moisture in the air condenses on the coil’s surface, reducing the humidity in the room.

Exhaust: The cooled and dehumidified air is then released back into the room through an exhaust vent.

This cycle repeats continuously until the desired indoor temperature is achieved. Portable air conditioners are designed for easy installation and mobility, allowing users to move them from one room to another, making them a flexible cooling solution for various spaces.

Comparison of mobile air conditioner refrigerants

There are several types of refrigerants used in mobile air conditioning systems. Here is a comparison of some commonly used refrigerants:

R-134a: This is a hydrofluorocarbon (HFC) refrigerant widely used in automotive air conditioning systems. It has low ozone depletion potential (ODP) and is considered environmentally friendly. However, it has a relatively high global warming potential (GWP).

R-1234yf: This is another HFC refrigerant that is gaining popularity as a replacement for R-134a. It has a significantly lower GWP, making it more environmentally friendly. It is used in many newer vehicle models.

R-410A: This is a hydrofluorocarbon blend used in residential and commercial air conditioning systems. It has no chlorine content, which makes it ozone-friendly. It has a relatively high GWP compared to some other refrigerants.

R-22: This hydrochlorofluorocarbon (HCFC) refrigerant has been widely used in older air conditioning systems. However, it is being phased out due to its ozone-depleting properties and high GWP. It is being replaced by more environmentally friendly alternatives.

R-290: This is a hydrocarbon (HC) refrigerant, specifically propane, which has a very low GWP and zero ODP. It is considered one of the most environmentally friendly refrigerants. However, due to its flammability, it requires special safety precautions during handling and storage.

Comparison of mobile air conditioner refrigerants

There are several types of refrigerants used in mobile air conditioning systems. Here is a comparison of some commonly used refrigerants:

R-134a: This is a hydrofluorocarbon (HFC) refrigerant widely used in automotive air conditioning systems. It has low ozone depletion potential (ODP) and is considered environmentally friendly. However, it has a relatively high global warming potential (GWP).

R-1234yf: This is another HFC refrigerant that is gaining popularity as a replacement for R-134a. It has a significantly lower GWP, making it more environmentally friendly. It is used in many newer vehicle models.

R-410A: This is a hydrofluorocarbon blend used in residential and commercial air conditioning systems. It has no chlorine content, which makes it ozone-friendly. It has a relatively high GWP compared to some other refrigerants.

R-22: This hydrochlorofluorocarbon (HCFC) refrigerant has been widely used in older air conditioning systems. However, it is being phased out due to its ozone-depleting properties and high GWP. It is being replaced by more environmentally friendly alternatives.

R-290: This is a hydrocarbon (HC) refrigerant, specifically propane, which has a very low GWP and zero ODP. It is considered one of the most environmentally friendly refrigerants. However, due to its flammability, it requires special safety precautions during handling and storage.

Portable Air conditioner energy efficiency rating introduction

An air conditioner energy efficiency rating, also known as an EER, is a measurement of how efficiently an air conditioning system uses energy to cool a space. It is a crucial factor to consider when purchasing an air conditioner, as a higher EER indicates a more energy-efficient unit.

The EER is calculated by dividing the cooling capacity of the air conditioner (in British Thermal Units, or BTUs) by the power input (in watts) required to run the unit. The result is a ratio that represents the cooling output per unit of energy consumed.

A higher EER means that the air conditioner can provide more cooling power while using less electricity. This translates into lower energy bills and a reduced environmental impact. In addition, energy-efficient air conditioners tend to have longer lifespans and require less maintenance.

The United States Department of Energy (DOE) has set minimum EER requirements for air conditioners, with higher minimums for larger units. These standards help consumers make informed decisions and promote the use of energy-efficient appliances.

When shopping for an air conditioner, it is important to look for the EER label or rating. The higher the EER, the more efficient the unit is. However, it is worth noting that higher EER ratings often come with a higher price tag. Therefore, it is essential to consider the balance between energy efficiency, initial cost, and long-term savings.

In conclusion, an air conditioner’s energy efficiency rating is a vital consideration for anyone looking to purchase a cooling system. It not only affects energy consumption and cost but also contributes to environmental sustainability. By choosing an air conditioner with a high EER, consumers can enjoy efficient cooling while minimizing their carbon footprint.

Portable Air conditioner energy efficiency rating introduction

An air conditioner energy efficiency rating, also known as an EER, is a measurement of how efficiently an air conditioning system uses energy to cool a space. It is a crucial factor to consider when purchasing an air conditioner, as a higher EER indicates a more energy-efficient unit.

The EER is calculated by dividing the cooling capacity of the air conditioner (in British Thermal Units, or BTUs) by the power input (in watts) required to run the unit. The result is a ratio that represents the cooling output per unit of energy consumed.

A higher EER means that the air conditioner can provide more cooling power while using less electricity. This translates into lower energy bills and a reduced environmental impact. In addition, energy-efficient air conditioners tend to have longer lifespans and require less maintenance.

The United States Department of Energy (DOE) has set minimum EER requirements for air conditioners, with higher minimums for larger units. These standards help consumers make informed decisions and promote the use of energy-efficient appliances.

When shopping for an air conditioner, it is important to look for the EER label or rating. The higher the EER, the more efficient the unit is. However, it is worth noting that higher EER ratings often come with a higher price tag. Therefore, it is essential to consider the balance between energy efficiency, initial cost, and long-term savings.

In conclusion, an air conditioner’s energy efficiency rating is a vital consideration for anyone looking to purchase a cooling system. It not only affects energy consumption and cost but also contributes to environmental sustainability. By choosing an air conditioner with a high EER, consumers can enjoy efficient cooling while minimizing their carbon footprint.

Portable Air conditioner filter introduction

An air conditioner filter is an essential component of an air conditioning system that helps improve indoor air quality by trapping dust, pollen, pet dander, and other airborne particles. It plays a crucial role in maintaining clean and healthy air in a space, as well as ensuring the proper functioning and efficiency of the air conditioner.

The primary function of an air conditioner filter is to capture and remove contaminants from the air as it circulates through the system. This helps to prevent these particles from being recirculated back into the room, reducing the risk of allergies, respiratory issues, and overall discomfort.

Air conditioner filters come in various types, including Negative Ion Filter, Activated Carbon Filter, Silver Ion Filter, Elimination Filter, and high-efficiency particulate air (HEPA) filters. Each type has different levels of filtration efficiency and lifespan, which should be considered based on individual needs and preferences.

Negative Ion Filter: This type of filter is designed to release negative ions into the air. Negative ions are believed to have various health benefits, such as improving mood, reducing stress, and enhancing overall well-being. They also help to remove airborne particles by causing them to stick together and fall to the ground, making them easier to clean.

Activated Carbon Filter: An activated carbon filter is effective in removing odors, chemicals, and volatile organic compounds (VOCs) from the air. It consists of a porous carbon material that adsorbs these pollutants, trapping them and preventing them from recirculating into the room. This type of filter is particularly useful in spaces with strong odors or for individuals with sensitivities to chemicals.

Silver Ion Filter: Silver ion filters are designed to inhibit the growth of bacteria, viruses, and mold within the air conditioning system. The filter contains silver-coated fibers or particles that release silver ions into the air, which have antimicrobial properties. This helps to maintain cleaner air and reduce the risk of respiratory infections.

Elimination Filter: High-density anti-mildew and washable filter screen is used; it can effectively remove dust. When the filter screen accumulates a certain amount, it is convenient to rinse the filter screen with clean water; to achieve cleaning, just put it back after drying.

HEPA Filter: High-Efficiency Particulate Air (HEPA) filters are known for their exceptional filtration capabilities. These filters can capture very small particles, including dust, pollen, pet dander, and even some bacteria and viruses. HEPA filters are highly effective in improving indoor air quality and are commonly used in environments where air purity is crucial, such as hospitals and laboratories.

It’s important to note that not all air conditioners come with these specialized filters as standard. Some filters can be added or replaced separately, depending on the specific needs and preferences of the user. When considering these specialized filters, it’s advisable to consult the air conditioner manufacturer or a professional to ensure compatibility and proper installation.

Regular maintenance and cleaning of the air conditioner filter are essential to ensure its optimal performance. Over time, the filter can become clogged with dirt and debris, reducing airflow and forcing the air conditioner to work harder, resulting in decreased energy efficiency. Therefore, it is recommended to clean or replace the filter periodically, following the manufacturer’s guidelines.

In addition to improving indoor air quality and energy efficiency, a clean and well-maintained air conditioner filter can also extend the lifespan of the air conditioner itself. By preventing the accumulation of dust and debris on the internal components, the filter helps to keep the system running smoothly and reduces the risk of breakdowns or malfunctions.

In conclusion, an air conditioner filter is a vital component of an air conditioning system that helps improve indoor air quality and maintain the efficiency of the unit. Regular cleaning and maintenance of the filter are crucial to ensure its effectiveness and prolong the lifespan of the air conditioner.

Portable Air conditioner filter introduction

An air conditioner filter is an essential component of an air conditioning system that helps improve indoor air quality by trapping dust, pollen, pet dander, and other airborne particles. It plays a crucial role in maintaining clean and healthy air in a space, as well as ensuring the proper functioning and efficiency of the air conditioner.

The primary function of an air conditioner filter is to capture and remove contaminants from the air as it circulates through the system. This helps to prevent these particles from being recirculated back into the room, reducing the risk of allergies, respiratory issues, and overall discomfort.

Air conditioner filters come in various types, including Negative Ion Filter, Activated Carbon Filter, Silver Ion Filter, Elimination Filter, and high-efficiency particulate air (HEPA) filters. Each type has different levels of filtration efficiency and lifespan, which should be considered based on individual needs and preferences.

Negative Ion Filter: This type of filter is designed to release negative ions into the air. Negative ions are believed to have various health benefits, such as improving mood, reducing stress, and enhancing overall well-being. They also help to remove airborne particles by causing them to stick together and fall to the ground, making them easier to clean.

Activated Carbon Filter: An activated carbon filter is effective in removing odors, chemicals, and volatile organic compounds (VOCs) from the air. It consists of a porous carbon material that adsorbs these pollutants, trapping them and preventing them from recirculating into the room. This type of filter is particularly useful in spaces with strong odors or for individuals with sensitivities to chemicals.

Silver Ion Filter: Silver ion filters are designed to inhibit the growth of bacteria, viruses, and mold within the air conditioning system. The filter contains silver-coated fibers or particles that release silver ions into the air, which have antimicrobial properties. This helps to maintain cleaner air and reduce the risk of respiratory infections.

Elimination Filter: High-density anti-mildew and washable filter screen is used; it can effectively remove dust. When the filter screen accumulates a certain amount, it is convenient to rinse the filter screen with clean water; to achieve cleaning, just put it back after drying.

HEPA Filter: High-Efficiency Particulate Air (HEPA) filters are known for their exceptional filtration capabilities. These filters can capture very small particles, including dust, pollen, pet dander, and even some bacteria and viruses. HEPA filters are highly effective in improving indoor air quality and are commonly used in environments where air purity is crucial, such as hospitals and laboratories.

It’s important to note that not all air conditioners come with these specialized filters as standard. Some filters can be added or replaced separately, depending on the specific needs and preferences of the user. When considering these specialized filters, it’s advisable to consult the air conditioner manufacturer or a professional to ensure compatibility and proper installation.

Regular maintenance and cleaning of the air conditioner filter are essential to ensure its optimal performance. Over time, the filter can become clogged with dirt and debris, reducing airflow and forcing the air conditioner to work harder, resulting in decreased energy efficiency. Therefore, it is recommended to clean or replace the filter periodically, following the manufacturer’s guidelines.

In addition to improving indoor air quality and energy efficiency, a clean and well-maintained air conditioner filter can also extend the lifespan of the air conditioner itself. By preventing the accumulation of dust and debris on the internal components, the filter helps to keep the system running smoothly and reduces the risk of breakdowns or malfunctions.

In conclusion, an air conditioner filter is a vital component of an air conditioning system that helps improve indoor air quality and maintain the efficiency of the unit. Regular cleaning and maintenance of the filter are crucial to ensure its effectiveness and prolong the lifespan of the air conditioner.

Motor of portable aircon introduction

Motor of portable aircon is mainly composed of the stator and the rotor. The stator is mainly composed of the iron core and the coil. The rotor is mainly composed of the shaft, the bearings, the commutator, the brushes, and other parts. The working principle of the portable air conditioner motor is that the current is passed through the coil of the stator to generate magnetic field, and the rotor is rotated by the magnetic force to generate airflow. The portable air conditioner motor is an important part of the portable air conditioner, and its performance directly affects the performance of the portable air conditioner.

Portable air conditioners typically use an electric motor for their operation. The motors used in portable ACs are typically classified based on their type and design. Here are three common motor classifications in portable air conditioners:

Single-phase induction motor: This type of motor is widely used in portable ACs due to its simplicity and cost-effectiveness. It operates on a single-phase AC power supply and consists of a stator (stationary part) and a rotor (rotating part). Single-phase induction motors provide reliable cooling and are commonly found in smaller portable AC units.

Permanent magnet motor: Some portable AC models utilize permanent magnet motors. These motors incorporate permanent magnets in the rotor, which enhance their energy efficiency and reduce power consumption. Permanent magnet motors are known for their compact size, lightweight, and ability to provide efficient cooling in portable air conditioners.

Brushless DC motor (BLDC): Brushless DC motors are becoming increasingly popular in portable air conditioners. These motors feature electronic commutation and do not require brushes for operation. BLDC motors offer higher energy efficiency, reduced noise levels, and longer lifespan compared to traditional brushed motors. They are known for their precise speed control, making them suitable for variable-speed compressor applications in portable ACs.

It’s important to note that while these motor classifications are commonly used in portable air conditioners, manufacturers may use different motor types or variations based on their specific design requirements.

Motor of portable aircon introduction

Motor of portable aircon is mainly composed of the stator and the rotor. The stator is mainly composed of the iron core and the coil. The rotor is mainly composed of the shaft, the bearings, the commutator, the brushes, and other parts. The working principle of the portable air conditioner motor is that the current is passed through the coil of the stator to generate magnetic field, and the rotor is rotated by the magnetic force to generate airflow. The portable air conditioner motor is an important part of the portable air conditioner, and its performance directly affects the performance of the portable air conditioner.

Portable air conditioners typically use an electric motor for their operation. The motors used in portable ACs are typically classified based on their type and design. Here are three common motor classifications in portable air conditioners:

Single-phase induction motor: This type of motor is widely used in portable ACs due to its simplicity and cost-effectiveness. It operates on a single-phase AC power supply and consists of a stator (stationary part) and a rotor (rotating part). Single-phase induction motors provide reliable cooling and are commonly found in smaller portable AC units.

Permanent magnet motor: Some portable AC models utilize permanent magnet motors. These motors incorporate permanent magnets in the rotor, which enhance their energy efficiency and reduce power consumption. Permanent magnet motors are known for their compact size, lightweight, and ability to provide efficient cooling in portable air conditioners.

Brushless DC motor (BLDC): Brushless DC motors are becoming increasingly popular in portable air conditioners. These motors feature electronic commutation and do not require brushes for operation. BLDC motors offer higher energy efficiency, reduced noise levels, and longer lifespan compared to traditional brushed motors. They are known for their precise speed control, making them suitable for variable-speed compressor applications in portable ACs.

It’s important to note that while these motor classifications are commonly used in portable air conditioners, manufacturers may use different motor types or variations based on their specific design requirements.

UnitedStar’s portable aircon uses all copper wire motor, running evenly and stably. Combined into a powerful refrigeration stably. Combined into a powerful refrigeration system, the air supply is more stable and safer, and the efficiency is higher.

The compressor of portable ac’s introduction and classification

Portable AC compressors can be classified based on their design and technology. Here are some common types:

Rotary Compressor: This type of compressor uses a rotating vane to compress the refrigerant. It operates with high efficiency and is known for its quiet operation. Rotary compressors are often found in higher-end portable AC units.

Reciprocating Compressor: Reciprocating compressors use a piston-cylinder arrangement to compress the refrigerant. This type of compressor is widely used in various cooling systems, including portable air conditioners. It offers good cooling performance but tends to be noisier compared to rotary compressors.

Scroll Compressor: Scroll compressors use two spiral-shaped scrolls to compress the refrigerant. They are known for their reliability, durability, and quiet operation. Portable air conditioners equipped with scroll compressors are often more expensive but provide efficient cooling.

Inverter Compressor: Inverter compressors are designed to vary their speed based on the cooling demand. By adjusting the compressor’s speed, they achieve precise temperature control and help save energy. Portable AC units with inverter compressors are becoming increasingly popular due to their energy efficiency and quieter operation.

It’s important to note that the availability of specific compressor types might vary among different portable AC models and manufacturers. When choosing a portable AC, considering the compressor type and its associated features can help you select a unit that fits your cooling needs and preferences.

UnitedStar’s portable ac adopts a high-efficiency rotary compressor, uses permanent magnet materials, is durable and does not demagnetize, and has more efficient power during operation, powerful cooling and heating, and quiet noise reduction.

UnitedStar’s portable aircon uses all copper wire motor, running evenly and stably. Combined into a powerful refrigeration stably. Combined into a powerful refrigeration system, the air supply is more stable and safer, and the efficiency is higher.

The compressor of portable ac’s introduction and classification

Portable AC compressors can be classified based on their design and technology. Here are some common types:

Rotary Compressor: This type of compressor uses a rotating vane to compress the refrigerant. It operates with high efficiency and is known for its quiet operation. Rotary compressors are often found in higher-end portable AC units.

Reciprocating Compressor: Reciprocating compressors use a piston-cylinder arrangement to compress the refrigerant. This type of compressor is widely used in various cooling systems, including portable air conditioners. It offers good cooling performance but tends to be noisier compared to rotary compressors.

Scroll Compressor: Scroll compressors use two spiral-shaped scrolls to compress the refrigerant. They are known for their reliability, durability, and quiet operation. Portable air conditioners equipped with scroll compressors are often more expensive but provide efficient cooling.

Inverter Compressor: Inverter compressors are designed to vary their speed based on the cooling demand. By adjusting the compressor’s speed, they achieve precise temperature control and help save energy. Portable AC units with inverter compressors are becoming increasingly popular due to their energy efficiency and quieter operation.

It’s important to note that the availability of specific compressor types might vary among different portable AC models and manufacturers. When choosing a portable AC, considering the compressor type and its associated features can help you select a unit that fits your cooling needs and preferences.

UnitedStar’s portable ac adopts a high-efficiency rotary compressor, uses permanent magnet materials, is durable and does not demagnetize, and has more efficient power during operation, powerful cooling and heating, and quiet noise reduction.

Heat exchanger of portable aircon introduction

A heat exchanger is a device used to transfer heat between two or more fluids that are at different temperatures, without them mixing with each other. It facilitates the efficient transfer of thermal energy from one fluid to another, either to heat or cool the fluids, depending on the application.

Heat exchangers are commonly used in various industries and applications, including heating, ventilation, and air conditioning (HVAC) systems, refrigeration units, power plants, chemical processing plants, and automotive engines, among others.

The basic principle of a heat exchanger involves the exchange of heat through a solid wall that separates the two fluids. The wall is usually made of a thermally conductive material, such as metal, and can be designed in various configurations to maximize heat transfer efficiency.

Heat exchangers can be classified into different types based on their design and flow arrangements. Some common types include:

Shell and Tube Heat Exchanger: This type consists of a shell (a cylindrical outer vessel) and multiple tubes inside it. One fluid flows through the tubes, while the other fluid flows around the tubes in the shell. This design offers high heat transfer efficiency and is widely used in various industries.

Plate Heat Exchanger: It consists of multiple thin plates, usually made of metal, stacked together with small gaps between them. The fluids flow through alternate channels formed between the plates, ensuring efficient heat transfer due to a large surface area.

Finned Tube Heat Exchanger: This type includes tubes with extended surfaces (fins) attached to the outer surface. The fins increase the heat transfer surface area, allowing for more effective heat exchange.

Air-to-Air Heat Exchanger: Also known as a heat recovery ventilator (HRV) or an energy recovery ventilator (ERV), this type transfers heat between two separate airstreams, typically in HVAC systems. It helps to recover the heat from exhaust air and pre-condition the fresh incoming air.

Heat exchangers play a crucial role in the efficient utilization of energy and conservation of resources. They enable the transfer of heat between fluids while minimizing energy losses, contributing to increased process efficiency and reduced energy consumption.

UnitedStar’s Double-row heat exchanger, toothed inner spiral copper tube, can effectively improve heat exchange efficiency and defrosting speed. Have great refrigeration.

Heat exchanger of portable aircon introduction

A heat exchanger is a device used to transfer heat between two or more fluids that are at different temperatures, without them mixing with each other. It facilitates the efficient transfer of thermal energy from one fluid to another, either to heat or cool the fluids, depending on the application.

Heat exchangers are commonly used in various industries and applications, including heating, ventilation, and air conditioning (HVAC) systems, refrigeration units, power plants, chemical processing plants, and automotive engines, among others.

The basic principle of a heat exchanger involves the exchange of heat through a solid wall that separates the two fluids. The wall is usually made of a thermally conductive material, such as metal, and can be designed in various configurations to maximize heat transfer efficiency.

Heat exchangers can be classified into different types based on their design and flow arrangements. Some common types include:

Shell and Tube Heat Exchanger: This type consists of a shell (a cylindrical outer vessel) and multiple tubes inside it. One fluid flows through the tubes, while the other fluid flows around the tubes in the shell. This design offers high heat transfer efficiency and is widely used in various industries.

Plate Heat Exchanger: It consists of multiple thin plates, usually made of metal, stacked together with small gaps between them. The fluids flow through alternate channels formed between the plates, ensuring efficient heat transfer due to a large surface area.

Finned Tube Heat Exchanger: This type includes tubes with extended surfaces (fins) attached to the outer surface. The fins increase the heat transfer surface area, allowing for more effective heat exchange.

Air-to-Air Heat Exchanger: Also known as a heat recovery ventilator (HRV) or an energy recovery ventilator (ERV), this type transfers heat between two separate airstreams, typically in HVAC systems. It helps to recover the heat from exhaust air and pre-condition the fresh incoming air.

Heat exchangers play a crucial role in the efficient utilization of energy and conservation of resources. They enable the transfer of heat between fluids while minimizing energy losses, contributing to increased process efficiency and reduced energy consumption.

UnitedStar’s Double-row heat exchanger, toothed inner spiral copper tube, can effectively improve heat exchange efficiency and defrosting speed. Have great refrigeration.

UnitedStar’s BSCI R290 Refrigerant 5 in 1 Portable AC

Portable air conditioner manufacturer UnitedStar’s mobile air conditioners stand out among the competition due to their exceptional features and functionality. Here are some key advantages and reasons why customers should consider choosing UnitedStar:

BSCI Certification: UnitedStar holds the Business Social Compliance Initiative (BSCI) certification, ensuring ethical and sustainable manufacturing practices.

R290 Innovative Refrigerant: UnitedStar mobile air conditioners utilize R290, an eco-friendly refrigerant with low environmental impact and excellent cooling performance.

Class A Energy Efficiency: UnitedStar units are rated Class A for energy efficiency, promoting energy savings while providing powerful cooling performance.

5 Functions in 1: UnitedStar mobile air conditioners offer five functions – refrigeration, heating, air supply, dehumidification, and purification. This versatility ensures year-round comfort and excellent air quality.

UnitedStar’s BSCI R290 Refrigerant 5 in 1 Portable AC

Portable air conditioner manufacturer UnitedStar’s mobile air conditioners stand out among the competition due to their exceptional features and functionality. Here are some key advantages and reasons why customers should consider choosing UnitedStar:

BSCI Certification: UnitedStar holds the Business Social Compliance Initiative (BSCI) certification, ensuring ethical and sustainable manufacturing practices.

R290 Innovative Refrigerant: UnitedStar mobile air conditioners utilize R290, an eco-friendly refrigerant with low environmental impact and excellent cooling performance.

Class A Energy Efficiency: UnitedStar units are rated Class A for energy efficiency, promoting energy savings while providing powerful cooling performance.

5 Functions in 1: UnitedStar mobile air conditioners offer five functions – refrigeration, heating, air supply, dehumidification, and purification. This versatility ensures year-round comfort and excellent air quality.

Activated Carbon and UVC Sterilizing Function: The inclusion of activated carbon and UVC sterilization technology in UnitedStar units guarantees cleaner and healthier air by eliminating harmful particles and bacteria.

Easy Mobility and Assembly: UnitedStar mobile air conditioners are designed for user convenience. With lightweight construction and smooth-rolling casters, they can be effortlessly moved from one room to another. Additionally, the units feature easy assembly for quick installation.

WIFI Function and LED Display: UnitedStar portable ac comes equipped with WIFI connectivity and LED displays, enabling remote control and providing a user-friendly interface for convenient operation.

Activated Carbon and UVC Sterilizing Function: The inclusion of activated carbon and UVC sterilization technology in UnitedStar units guarantees cleaner and healthier air by eliminating harmful particles and bacteria.

Easy Mobility and Assembly: UnitedStar mobile air conditioners are designed for user convenience. With lightweight construction and smooth-rolling casters, they can be effortlessly moved from one room to another. Additionally, the units feature easy assembly for quick installation.

WIFI Function and LED Display: UnitedStar portable ac comes equipped with WIFI connectivity and LED displays, enabling remote control and providing a user-friendly interface for convenient operation.

We have 1133 kinds of products, among them, 82 have their property rights. We mainly produce portable air conditioner, air cooling fans, electric fans, ceiling fans, rechargeable fans, solar fans, and BLDC motors. The group has its own freight forwarding company and has more initiative in trailer and sea transportation. United Star has six registered trademarks, more than 30 product patents, GS/CE/CB/SAA/RoHS/SASO/CCC, and other certificates.

Portable air conditioner manufacturer United Star has six R&D engineers, an average of 13 new products are developed every year. Our products are exported to 126 countries, we wholeheartedly for customers to provide OEM and ODM services, have cooperated with famous enterprises at home and abroad, such as French Carrefour supermarket, German Lidl supermarket, Indian Orient company, and so on. Since 2019, the sales growth rate of our own

brand United Star in the global market has exceeded 250% for three consecutive years. Meanwhile, we have cooperative assembly bases in Indonesia, Tunisia, Mexico, Nigeria, and other regions. ” To be the most reliable environmental air cooling appliance provider. Committed to the comfort and environmental protection of the family and the earth environment ” is our persistent goal.

We have 1133 kinds of products, among them, 82 have their property rights. We mainly produce portable air conditioner, air cooling fans, electric fans, ceiling fans, rechargeable fans, solar fans, and BLDC motors. The group has its own freight forwarding company and has more initiative in trailer and sea transportation. United Star has six registered trademarks, more than 30 product patents, GS/CE/CB/SAA/RoHS/SASO/CCC, and other certificates.

Portable air conditioner manufacturer United Star has six R&D engineers, an average of 13 new products are developed every year. Our products are exported to 126 countries, we wholeheartedly for customers to provide OEM and ODM services, have cooperated with famous enterprises at home and abroad, such as French Carrefour supermarket, German Lidl supermarket, Indian Orient company, and so on. Since 2019, the sales growth rate of our own

brand United Star in the global market has exceeded 250% for three consecutive years. Meanwhile, we have cooperative assembly bases in Indonesia, Tunisia, Mexico, Nigeria, and other regions. ” To be the most reliable environmental air cooling appliance provider. Committed to the comfort and environmental protection of the family and the earth environment ” is our persistent goal.