As a necessary household appliance, fans and air conditioners play an important role in people’s lives. Aspects of quality, performance and reliability of fans and air conditioners are largely dependent on the accessories used with them. Therefore, in order to ensure the quality and stability of products, many factories choose to produce accessories by themselves,including Fan Factory UniedStar company. Let us discuss the below 5 reasons why we produce accessories by ourselves.

Firstly, the in-house production of components ensures quality control. The performance and reliability of fans and air conditioners are largely affected by accessories. If the factory outsources the production of accessories to other manufacturers, it will be difficult to grasp the quality standards and production process of accessories. When the factory produces accessories by itself, it can strictly control the production process, and formulate corresponding quality management measures to ensure that the quality of accessories is stable and reliable.

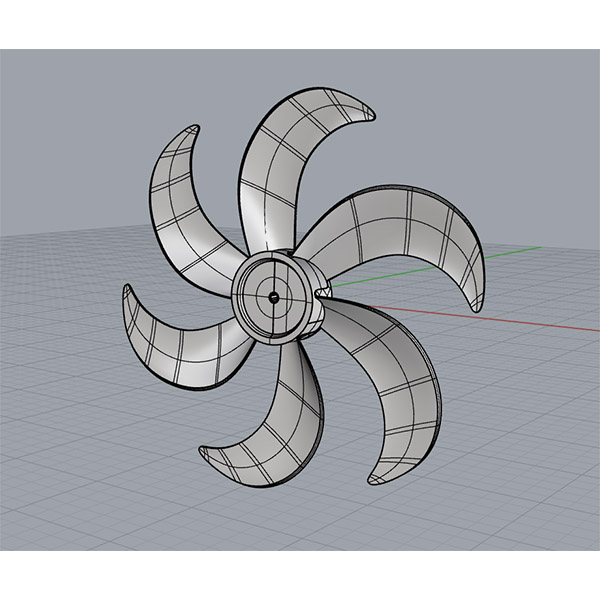

For example, color difference, electric motor control, wind blade balance, large-scale sample retention, etc., because fan supplier UnitedStar has its own factory, it can better control the quality of the production process. At the same time, because there are many molds in our factory, if a customer wants to change the shape of the mold, we can easily solve the problem of mold modification, saving time and cost for customers.

Secondly, independent production of accessories can improve production efficiency. By producing components themselves, own factories can better control the supply chain and production process. There is no need to rely on external suppliers, and will not be affected by problems such as unstable parts supply or delivery delays. This can avoid the shutdown of the production line due to lack of spare parts, and improve production efficiency, ensure timely delivery of products.

Thirdly, the in-house production of components helps to reduce costs. Although the production of accessories requires investment in certain production equipment and human resources, but in the long run, self-produced accessories can bring cost savings. The cost of purchased parts usually includes the supplier’s profit and logistics costs, etc., and the production of parts can reduce this part of the cost, thereby reducing the overall production cost and enhancing the competitiveness of the enterprise.

In addition, the in-house production of accessories can also promote innovation and technological progress. By producing accessories by ourselves, self-owned factories can better understand and master the technical characteristics and process requirements of accessories. This provides more space for technology research and development and product innovation of enterprises. In the process of independently producing accessories, the factory can also continuously improve and optimize the design and manufacturing process of accessories, and promote the technological progress of the entire industry.

Finally, the production of accessories in-house helps to provide customized products and services. Different fans may require accessories of different specifications, and suppliers of outsourced accessories may not be able to meet individual requirements. By producing accessories by ourselves, the self-owned factory can flexibly customize the specifications, materials and performance of accessories to meet the needs of the market and customers, provide more personalized products and services as well. Thereby enhance competitiveness and provide consumers with better products and experiences.

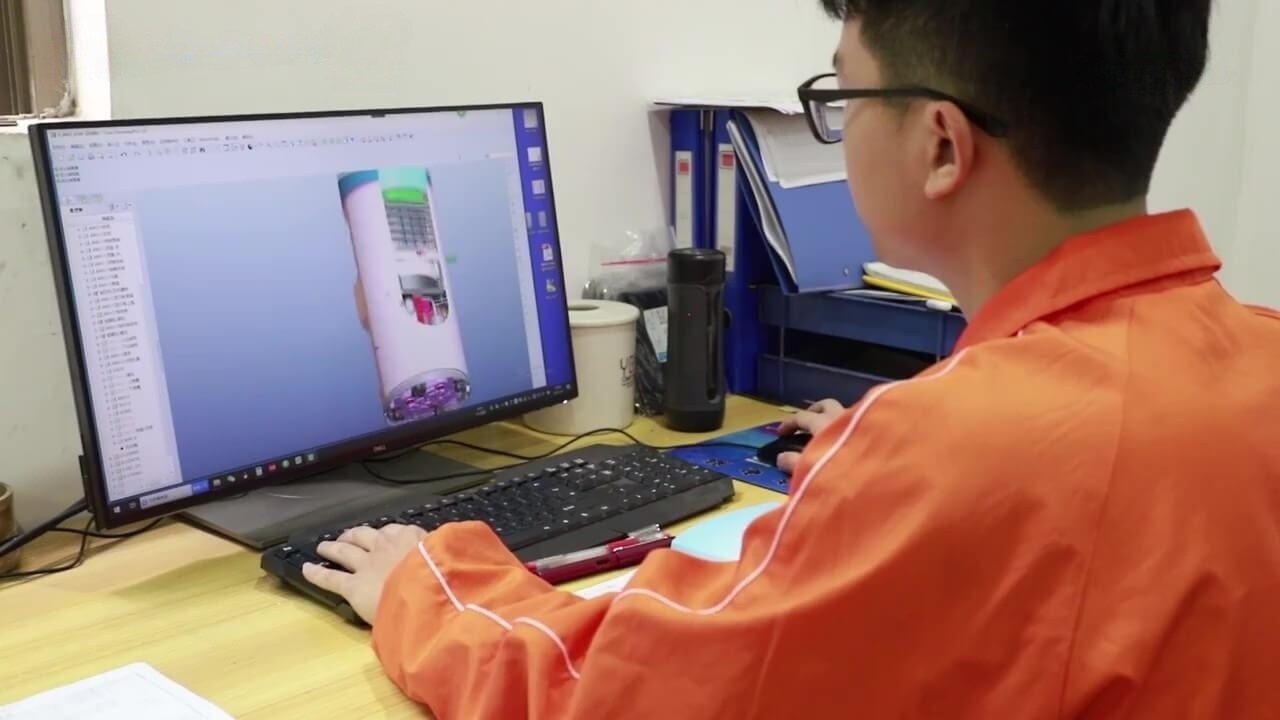

Fan Factory UnitedStar has 2 factories in Zhongshan City, Guangdong Province, including factories that produce electric fans and portable air conditioners. We have nearly 30,000 square meters of factory buildings that have passed the ISO9001 quality system and BSCI certification system, including hardware, motors, injection molding, and grilles. , 6 workshops for final assembly. With international advanced R290 mobile air conditioner production line and enthalpy difference laboratory and other advanced equipment.

There are some engineers in the R&D department of UnitedStar. On average, 13 new products are developed every year. The products are exported to more than 120 countries abroad. We wholeheartedly provide OEM and ODM services to our customers.